'Who Pays?' finds more shops seek payment for color match camera use, 86% paid for blending adjacent panels | Repairer Driven News

More than 1 in 5 shops now say they have billed insurers for the labor time required to set up and use a spectrophotometer, or color match camera, according to the quarterly “Who Pays for What?” survey completed earlier this year.

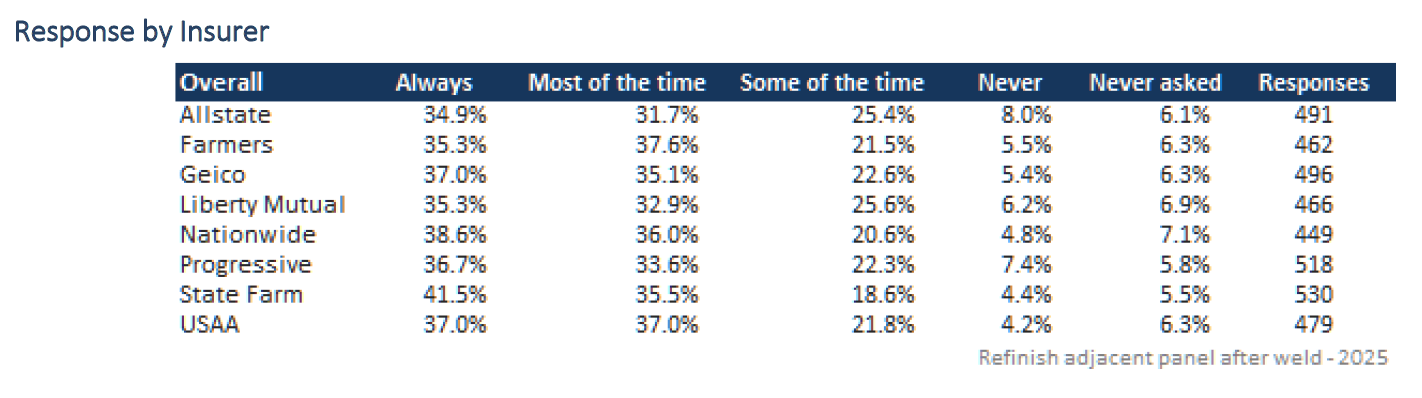

The survey also found that a higher percentage of shops are being paid regularly for the procedure by eight of the largest national insurance companies.

“We only started asking this question two years ago,” said shop consultant Mike Anderson, of Collision Advice, in a press release.

Collision Advice conducts the quarterly “Who Pays” surveys with CRASH Network.

“In that time, the percentage of shops who believe that insurers ‘never’ pay for this procedure has dropped from 71% to 65%, while the number of shops saying they are paid for it ‘always’ or ‘most of the time,’ has grown,” he said.

In response to inquiries submitted through the Database Enhancement Gateway (DEG), all three major estimating system providers have confirmed that using a spectrophotometer to determine a color code formulation is not included in published refinish labor times.

“As automakers come out with more variations of colors, the use of a camera can become even more critical,” Anderson said, in the release. “It can be a not-inconsiderable amount of time in that you may have to buff or clean the panel prior to using the camera, and ensure you have the vehicle or panel placed in certain lighting conditions.”

The survey, fielded in January, focused on refinish operations.

The findings also show that 86% of shops that negotiate for color-match labor to blend adjacent panels are always paid or paid most of the time. Compared to last year, that figure is 1.5 percentage points lower.

State Farm, Nationwide, and USAA are the top three companies that always pay for the operation. All eight insurers always pay between 55% and 60% of the time.

In July, two years after the completion of the Society of Collision Repair Specialists (SCRS) blend study, there had been improvements on prior estimating system guidance for blending but more education and conversation are needed for many repair shops to influence compensation, according to a panel held during a Collision Industry Conference (CIC) meeting.

While many estimating platforms have removed prior guidance — replacing specific blend formulas with instruction to use on-the-spot evaluations — the market is facing growing pains as some insurance companies remain reliant on a now outdated approach.

A CRASH Network survey last fall (October) found that 70% of the more than 400 responding shops were aware of the changes their estimating system provider made in terms of the blend time formula. However, about 2 in 5 (41%) said they rarely or never receive more than 50% of full refinish time for the blending operation.

At the other end of the spectrum, more than 1 in 4 (28%) said they usually or always collect more than the 50% formula for blend times. The rest of the shops (31%) fall somewhere in between, saying they sometimes get more than 50% of full refinish time.

Another topic included in the new “Who Pays” survey addressed labor to refinish areas on repaired adjacent/mating panels following damages during removal of a welded-on or riveted/bonded panel, shops saw an increase this year in payment by insurance companies of 2 percentage points to 72%.

In the survey report, Anderson encourages shops to include the operation on estimates and itemize each step rather than including a lump sum amount.

“When you replace a quarter-panel, for example, there are more than two dozen items you may need to paint because of weld burn damage,” Anderson wrote. “Replacing a rear body panel, for example, you may need to refinish (among other areas): the top and bottom of the trunk flood and gutters; the inner and outer quarter panels and quarter extensions; the left and right rear frame rails; and possibly, the inner and outer tail light pockets.

“Remember that refinish labor times are for one side only, so keep ‘inner/outer’ and ‘top/bottom’ in mind. It amazes me and scares me when I go into shops that are using 1k products on the back side of panels. No OEM approves the use of a 1k product as it is not resistant to UV rays or corrosion.”

Anderson also noted some shops have reported pushback from insurance companies on labor to extend clear coat to its natural breaking point on laser welded roofs. According to the survey results, shops being paid most or all of the time for the operation in general decreased by 1.5 percentage points to 77%.

Anderson recommends shops visit the clearcoat blending section of the OEM1Stop Position Statements page to see statements from OEMs on the procedure. The survey report also includes resources, including documentation from paint companies.

Earlier this week, Axalta released a recommendation document that states applying clearcoat to the entire panel is the traditional industry practice to restore a late model vehicle to its pre-accident condition and it is a requirement for warrantied systems supplied by the company.

Axalta notes in the document that “it is critical to the quality of the repair to use the recommended products following the approved processes outlined in Axalta’s Technical Data Sheets.”

The latest quarterly “Who Pays for What?” survey is now open through the end of the month, and can be taken here. It focuses on not-included frame and mechanical labor operations.

The survey can be completed in about 15 minutes by anyone familiar with their shop’s billing practices and the payment practices of at least some of the largest national insurers. Each shop’s responses are held in the strictest confidence; only aggregated data is released.

Survey participants receive a free report with complete survey findings as well as analysis and resources to help shops better understand and use the information presented.

The results of previous surveys are also available here.

Images

Featured image: A portion of the week-long blend study coordinated by SCRS is shown at the Global Finishing Solutions (GFS) Center for Excellence, at the GFS headquarters in Osseo, Wisconsin, in August 2022. (Credit: SCRS)

Charts provided by Collision Advice/CRASH Network

Share This: