The Q&A: Helping box-makers boost efficiency as e-commerce booms | Spectra by MHI

What does a typical day at work look like for you? What is your favorite aspect of your job? How does your work help move the world forward? What recent project are you proud of contributing to? What keeps you awake at night? What’s the most valuable lesson you have learned in your career? Where do you see the world in 2050?

We’re all used to clicking ‘buy’ online and a neatly packaged box arriving at our door soon after. Most of us are only concerned with the contents — but Christine Little spends her days thinking about the box itself.

As Director of Sales in the Corrugating Machinery Division at Mitsubishi Heavy Industries (MHI) America, she is responsible for selling industrial box-making and corrugating machines manufactured by MHI Machinery Systems to the North American market.

It’s an industry that’s experiencing significant growth as e-commerce booms and demand rises for more sustainable packaging solutions — providing Christine and her team with some challenges and many opportunities.

A typical day for me is all about our customers. I handle the North American market, which is Canada, the United States and Mexico — I just got back last night from a meeting in Mexico City.

Since the pandemic, which saw a surge of people ordering from home and higher demand for box companies’ products, there has been an increasing amount of interest in our machinery because of the high levels of productivity it provides.

My job is to service both existing customers and new inquiries — and this can involve liaising with teams across MHI all over the world.

I came to MHI after a long career in the box-making sector, so it’s fair to say I have a soft spot for the industry. I feel proud that I can help companies continue their growth with MHI machines at the heart of their operations.

Because of my background in the business, I understand industry issues and how to resolve them.

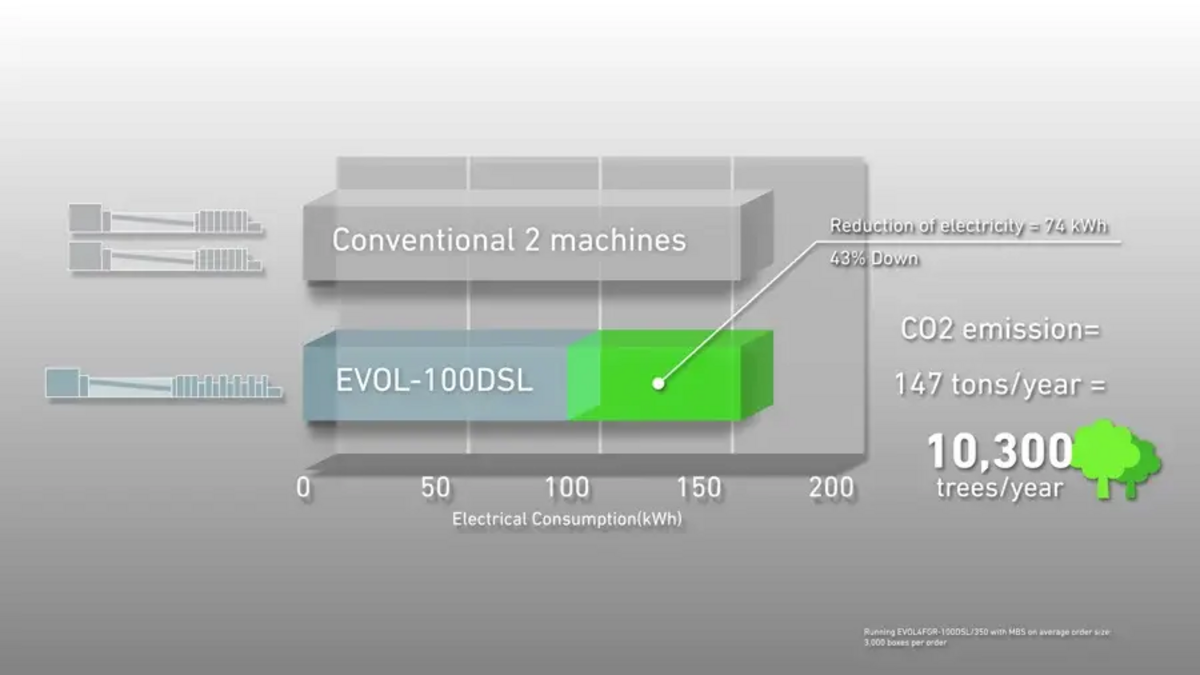

The corrugated packaging industry has made a lot of progress on its environmental impact in recent years, but there is always more that can be done. A lot of equipment in box plants has been in use for a long time, for example. In many cases, you could swap two or even three older machines for one of MHI’s models and make savings across the board — they use less electricity, water and ink, for example.

They also help boost productivity and address staffing issues or skills gaps. Research shows global talent shortages are at record highs and our industry is no different — many companies are struggling to find qualified people to run their equipment. Modern machines can halve the number of operators needed, freeing up workers’ time so they can be reallocated to work in other areas of the plant.

When I joined the company, we were a small division of MHI based in Baltimore, Maryland, and I’m not sure many people knew who we were. I think we had about 50 people back then — today, we’re still in Baltimore and our team here is now about 130-strong.

We have had huge growth and recognition within the industry. We’ve worked hard to increase our presence at trade shows, on social media and our marketing program has evolved to really raise awareness of the efficiency and sustainability benefits of our machines.

I understand that every minute of downtime box companies experience is money out of their pocket. We work hard to give our customers the tools to keep their machines running efficiently.

A big part of this is never standing still — we’re always asking questions such as what we could do differently, what new initiatives could we start, what do we need to do to ensure we continue to be the gold standard?

Humility. We’ve had lots of wins over the past few years but we have also had some challenging moments. But that just keeps you humble and motivated to be the best you can be.

I think we are just scratching the surface of some of the issues that will emerge from the climate crisis that we will have to adapt to. That’s why I am so proud to work for MHI — the company is serious in its commitment to net zero and always innovating in this space; it’s never stagnant.

David Elliott

David Elliott has two decades’ experience working as a journalist, communications professional and content creator, including for some of the world’s biggest technology brands.

![]()

You may also like...

Diddy's Legal Troubles & Racketeering Trial

Music mogul Sean 'Diddy' Combs was acquitted of sex trafficking and racketeering charges but convicted on transportation...

Thomas Partey Faces Rape & Sexual Assault Charges

Former Arsenal midfielder Thomas Partey has been formally charged with multiple counts of rape and sexual assault by UK ...

Nigeria Universities Changes Admission Policies

JAMB has clarified its admission policies, rectifying a student's status, reiterating the necessity of its Central Admis...

Ghana's Economic Reforms & Gold Sector Initiatives

Ghana is undertaking a comprehensive economic overhaul with President John Dramani Mahama's 24-Hour Economy and Accelera...

WAFCON 2024 African Women's Football Tournament

The 2024 Women's Africa Cup of Nations opened with thrilling matches, seeing Nigeria's Super Falcons secure a dominant 3...

Emergence & Dynamics of Nigeria's ADC Coalition

A new opposition coalition, led by the African Democratic Congress (ADC), is emerging to challenge President Bola Ahmed ...

Demise of Olubadan of Ibadanland

Oba Owolabi Olakulehin, the 43rd Olubadan of Ibadanland, has died at 90, concluding a life of distinguished service in t...

Death of Nigerian Goalkeeping Legend Peter Rufai

Nigerian football mourns the death of legendary Super Eagles goalkeeper Peter Rufai, who passed away at 61. Known as 'Do...