Chancellor's Innovation Fund Backs Six Budding Inventions

At NC State University, we believe the research of today enables the solutions of tomorrow. Nearly all new products and processes, from medical devices and drug development to semiconductor chips and self-driving cars, require many years of early-stage research before they’re ready to reach the market. And much of that research starts at universities like NC State.

Randy Woodson was well aware of that when he took the reins as chancellor, and as the leader of a land-grant university, he also knew it was his job to help ensure NC State research benefits the citizens of North Carolina and beyond.

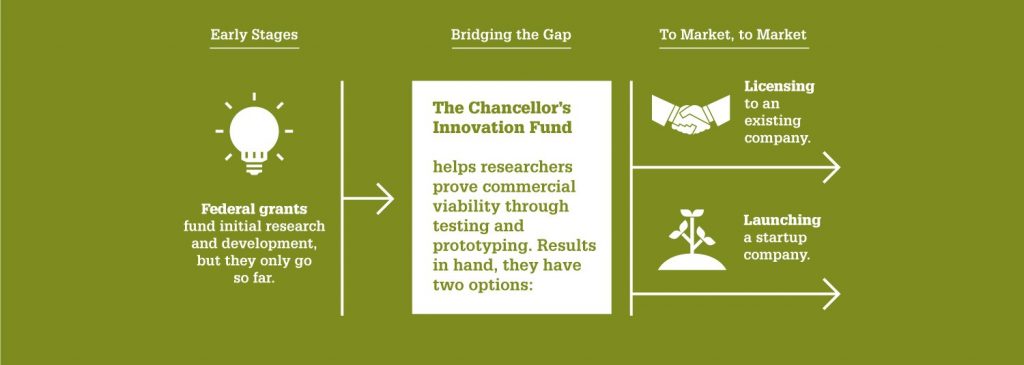

That’s why one of the first things he did was establish the Chancellor’s Innovation Fund (CIF). The CIF, established in 2010, awards support to short-term, commercially focused research projects. Each year, a select few promising proposals are chosen based on their likelihood of market success, as well as their potential societal benefits.

“One of the biggest challenges that universities face — particularly at a place like NC State that has so many diverse technologies — is that faculty can advance their innovations to a certain point but often lack the funding to reach the point where they can really be successful with a startup company or technology commercialization,” Woodson said at his final CIF awards reception.

With funds from the sale of stock owned in one of NC State’s many successful spinout companies, Woodson launched the CIF. It turned out to be an incredible return on investment.

For every dollar the CIF has awarded, it’s generated close to $20 in additional funding or investment.

“We’ve funded many faculty through this fund and started a number of companies, which have returned to the university over $7 million in licensing revenue,” Woodson said.

In 2023, the CIF was bolstered by a major gift from local entrepreneur and investor Bill Spruill, creating the 2ndF Research Commercialization Fund.

To date, the CIF and 2ndF programs have granted nearly $6 million to 87 projects, which have attracted over $166.6 million in follow-on funding. These projects have led to 39 startup companies, 68 commercialization agreements and $6.7 million in licensing revenue.

When Chancellor Woodson retires next month, the CIF is one of several initiatives that will help cement his legacy as one of the most transformative leaders in our university’s history. Under Woodson’s leadership, NC State’s research enterprise reached record heights. In fiscal year 2017, NC State’s research expenditures exceeded $500 million for the first time in the university’s history and have exceeded or met that level ever since.

The spur in research funding also helped foster entrepreneurship across campus. NC State has generated more than 190 start-ups and spinoffs during Woodson’s tenure, adding more than $1.2 billion to North Carolina’s economy every year. In the past five years alone, there have been more than 1,000 invention disclosures, 700 commercialization agreements, 350 patents issued, and nearly 975 new patents filed.

This year’s CIF awardees are exploring how to ensure endpoint cybersecurity in the era of quantum computing; make veterinary eye surgeries safer; replace plastic foam with a biodegradable alternative; help farmers grow more crops with less fertilizer; and enhance a cutting-edge gene-editing technique that uses electrical pulses to deliver DNA into cells.

To learn more about this year’s projects, continue reading.

It’s fairly common for cats, dogs and other pets to get wounds on their eyes. For roughly 10% of our furry friends, unfortunately, these surface injuries worsen to the point that surgery is required. Certain dog breeds — pugs and bulldogs, for example — are especially prone to ocular ulcerations.

Veterinary surgeons often treat these wounds with a fibrous mesh — typically derived from human donor tissue and known as an amniotic membrane (AM) — that effectively serves as a bandage and can also deliver transplanted cells to improve healing. While considered the gold standard in surgical options, AMs still have several limitations. Namely, the inherent variation of donor tissue means careful processing is needed to ensure the AM is safe and will be accepted by its recipient.

Brian Gilger, a professor in the Department of Clinical Sciences, and Jessica M. Gluck, an assistant professor in the Department of Textile Engineering, Chemistry and Science, have developed an animal-free alternative to amniotic membranes. Made from a synthetic polymer, their fibrous mesh is surface-treated to ensure it retains the same essential properties of donor-derived meshes.

CIF and 2ndF support will be used to perform in vivo compatibility tests and connect with potential customers and partners.

In terms of weight, the world grows more corn than any other crop. Largely due to how fast it grows, corn is a staple food for over a billion people across the planet. However, corn also needs more fertilizer per acre than any other major crop.

Christine Hawkes, a professor of plant and microbial biology, and Saad Khan, a professor of chemical and biomolecular engineering, believe endophytic fungi that live inside roots could help farmers grow more crops — with less fertilizer. The idea is to leverage naturally occurring nitrogen, a key ingredient in commercial fertilizers. Fungi can access nitrogen directly from organic matter like compost and manure, whereas plants cannot. Hawkes and Khan are investigating how the endophytic fungi can help plants absorb these nutrients.

So far, Hawkes and Khan have only tested their approach on switchgrass. But they’re hopeful the results will translate to food crops. If they’re able to demonstrate viability for corn, their technique could theoretically be applied to nearly any other crop, as similar endophytic fungi have been found in every plant that scientists have studied.

CIF and 2ndF support will be used to optimize the endophytic fungi delivery method for corn and explore the potential of forming a startup company to further commercialize the technology.

Estimates indicate plastic foam accounts for up to a third of landfill waste worldwide. Widely used in packaging materials, plastic foam is neither biodegradable nor easy to recycle. With regulations against plastic foam already being enacted, shipping companies are seeking sustainable alternatives.

Researchers in the Department of Forest Biomaterials — Richard Venditti, Joel Pawlak and Alfonso Dominguez Gonzalez — might have an answer. They’ve developed a proprietary mix of natural fibers that can be used to produce lightweight cushioning.

The fiber-based material is completely biodegradable, and it could one day replace synthetic and petroleum-based packaging materials. If used in place of polystyrene foam in paperboard packaging applications, the biobased cushioning material could be fully incorporated into the paper recycling process.

CIF and 2ndF support will be used to manufacture a prototype material at lab scale and engage with prospective industry partners.

For all the promise the power of quantum computing holds, it presents an equal if not greater threat. Perhaps foremost among the potential concerns is what hackers could do with a quantum computer at their disposal. Simply put, we’ll need entirely new encryption methods to protect our data from falling into the wrong hands. Once fully realized, a quantum computer could theoretically break any classical computing system’s cryptography in a matter of minutes.

Researchers in the Department of Physics, Shuang Fang Lim and Robert Riehn, want to create a pocket-sized smart card that could help users protect their devices from quantum cyberattacks. Lim, whose expertise is in materials physics and applications, and Riehn, whose expertise is in device nanofabrication, have a track record of collaborations. Other cybersecurity solutions have been developed, but Lim and Riehn say the best competition currently on the market is the size of a server rack.

CIF support will be used to develop a prototype for lab testing.

When farmers put fertilizer down, most of it never gets to their crops. Much of it ends up in runoff water, and most of what’s absorbed into the ground stays in the soil rather than reaching the roots. Meanwhile, the phosphates that make up one of the main ingredients in all fertilizers are becoming an increasingly finite resource.

Kirill Efimenko and Jan Genzer, researchers in the Department of Chemical and Biomolecular Engineering, think they’ve found a way to capture — and reuse — wasted phosphates, making fertilizer more cost-efficient and environmentally friendly at the same time. Efimenko and Genzer are developing a polymer gel that can filter phosphates from runoff water. What’s more, the filtering process yields highly purified phosphates that can be used again in fertilizers several times over.

CIF and 2ndF support will be used to test the process commercially with an industry partner.

Until the ‘80s, nearly all drugs were made the same way — chemical synthesis, a series of chemical reactions to form a complex compound. Nowadays, though, many therapeutics are manufactured entirely differently, mostly through some form of genetic engineering. Gene-editing platforms like CRISPR opened the door for revolutionary treatments once unimaginable. But even the most cutting-edge tools take time — and often a lot of trial-and-error — to manufacture biologics such as antibodies, mRNA vaccines and CAR-T cell therapies.

In addition to CRISPR, viral vectors and electroporation are the two other leading methods used to genetically engineer modern-day medical treatments. To deliver genetic material into cells, the former leverages modified viruses while the latter uses electrical pulses.

Mike Sano, a professor in the Lampe Joint Department of Biomedical Engineering, has developed a proprietary technology platform that could significantly improve the efficiency of existing electroporation techniques, which cause a lot of collateral damage — killing up to 80% of the target cells inadvertently. Dubbed “Algorithmically Controlled Electroporation,” or ACE for short, Sano’s approach uses ultrashort nanosecond electrical pulses to push genetic material into cells.

CIF and 2ndF support will be used to scale up the platform and conduct customer discovery, which will include working with a prospective industry partner in the Triangle area.