Nabhdrishti Aerospace secures $3 million funding to develop fuel-flexible gas turbine engines

Led by Accel and joined by IIMA Ventures, the funds will help test prototypes and conduct flight trials. The technology aims to reduce India's dependence on imported propulsion systems and offer versatile dual-use applications.

Nabhdrishti Aerospace, a Bengaluru-based aerospace startup, secured $3 million in seed funding to develop fuel-flexible gas turbine engines. The funding round, led by Accel with participation from IIMA Ventures and other investors. The company aims to reduce India's reliance on imported propulsion systems. The funding will support engine prototype testing, flight trials, and team expansion.

Founded by former GE, Rolls-Royce, and DRDO-GTRE engineers, Nabhdrishti Aerospace is developing a dual-use micro gas turbine engine platform. This platform will power both aircraft and industrial applications. The company is led by Rohit Chouhan, Arjun Srivatsa, and Antanu Sadhu, graduates of IIT Delhi, IIT Kanpur, and IISc, respectively.

“India’s dependence on imported propulsion systems has long constrained our aerospace ambitions,” said Rohit Chouhan, co-founder and CEO of Nabhdrishti Aerospace.

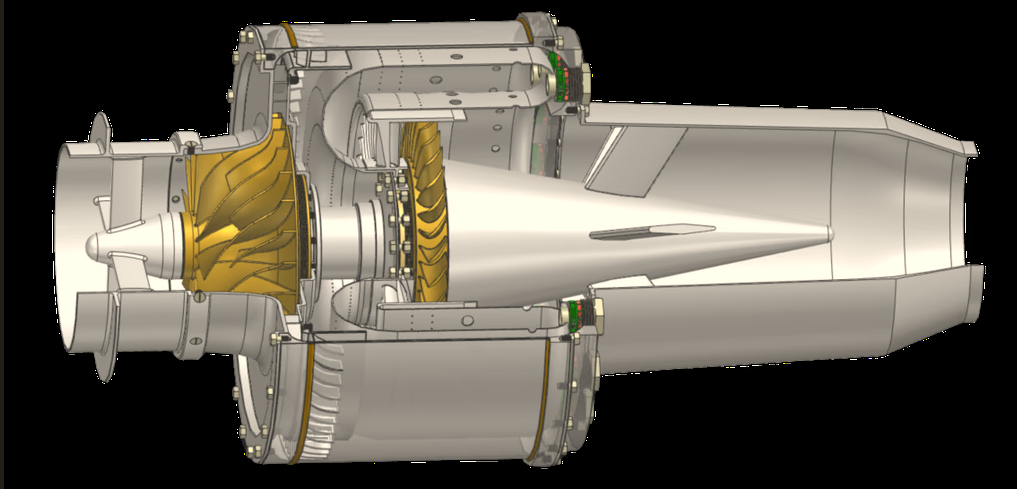

Nabhdrishti Aerospace is focused on developing two engine models: the ND400 and ND2000. These engines share a common core micro gas turbine design.

The ND400 engine targets unmanned aerial vehicles (UAVs) and hybrid electric aircraft, providing up to 400 shaft horsepower. The ND2000 engine is designed for industrial and defense applications, offering up to 2 megawatts of power output. This engine can provide power generation for various purposes, including backup power systems.

Where it would be utilised?

The $3 million seed funding will enable Nabhdrishti Aerospace to accelerate its engine development program. The company plans to construct and test three engine prototypes. These prototypes will undergo rigorous testing to validate their performance and reliability.

Nabhdrishti Aerospace will collaborate with UAV manufacturers to conduct flight trials with the ND400 engine. These trials will provide real-world performance data and demonstrate the engine's capabilities. The flight tests will be crucial for securing future contracts.

The company aims to generate early revenue by focusing on supplying micro turbines for UAVs and backup power systems. This will provide valuable market feedback and establish the company's presence in key sectors. This early revenue will also help support ongoing research and development efforts.

Workforce expansion

Nabhdrishti Aerospace is committed to expanding its workforce by the end of 2025. The company plans to hire engineers, production personnel, and customer support staff. This expansion will support the company’s growth and its ability to meet customer demands.

The company intends to progressively scale its workforce over the next few years. This scaling will align with the expansion of its product portfolio and customer base. Nabhdrishti Aerospace’s long-term vision includes establishing itself as a leading provider of aerospace propulsion systems.

The engines developed by Nabhdrishti Aerospace incorporate several key features designed to improve performance, efficiency, and sustainability. These features position the company to be competitive in the aerospace market. They also address evolving industry demands for cleaner and more efficient propulsion systems.

Nabhdrishti Aerospace usage of advanced technologies

Nabhdrishti Aerospace has developed a Fuel-Flex Combustor. This combustor is capable of burning both conventional fuels and sustainable alternatives. The ability to use green hydrogen aligns with global decarbonisation efforts. It also provides operational flexibility for customers in diverse markets.

Nabhdrishti Aerospace utilizes 3D printing in its manufacturing processes. Additive manufacturing enables the creation of elegant, lightweight designs at a lower cost compared to traditional methods. 3D printing also accelerates production timelines. This allows the company to respond more quickly to market demands. The reduced manufacturing costs enhance the affordability of the engines.

- Published On Mar 30, 2025 at 11:43 AM IST